DRA PAT Testing – Newcastle upon Tyne – based electrical equipment testing experts

With over 15 years’ experience, over 500 Five-Star reviews we are the trusted choice for Portable Appliance Testing in Newcastle upon Tyne, throughout Tyne and Wear, parts of Northumberland and East Durham.

We offer top quality, no fuss solutions for ensuring your electrical equipment is safe, with guidance on sensible retest periods, free repairs, retest reminders and fully compliant PAT Testing Certificate Reports. We are CHAS accredited and PATTA members.

We make sure your electrical equipment is safe – and we make the process as easy as possible for you.

We specialise in professional, reliable and fully compliant PAT testing for businesses, landlords, schools, trades and organisations of all sizes. Our fully qualified, highly trained technicians deliver thorough inspections, remedial repairs, clear documentation and peace of mind; all with a friendly service and no hidden costs.

✅ Fully certified and Insured (£10m PLI)

✅ Fast turnaround & digital reports

✅ Transparent Pricing with no hidden costs

✅ Flexible appointments to suite you

✅ Over 500 5-star reviews from happy clients.

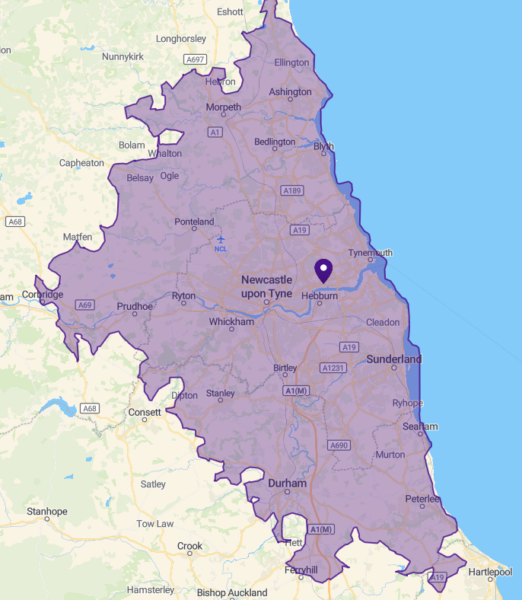

PAT Testing North East – Areas We Cover

With technicians based in Newcastle, North Shields, Wallsend, Sunderland and Seaham, we are easily able to cover the North East region. Our office is in North Shields, where if you have just a few items to test you can bring them to us. If you’re within 30 minutes drive our standard initial prices apply. For further afield we charge a little bit extra to cover the travel time. See our prices page for more information.

If you have sites elsewhere in the UK

Some of our clients have sites elsewhere in the UK; we are able to service them too. Whilst our technicians mainly work in the North East, we do have some trusted contractors we use for work throughout the UK, such as in London, Yorkshire and the North West.

Fully Compliant Inspection and Testing of Electrical Equipment

Inspection

We visually inspect every item for signs of damage or defects before testing. Catching issues early to ensure equipment is safe to use. We also make sure equipment is suitable for use.

Testing

We use industry leading calibrated PAT Testing equipment to check for earth continuity, insulation resistance and polarity; making sure each item meets the legal standards for electrical safety.

Repair

If we find any minor faults such as a broken plug or incorrect fuse, we carry out quick, free, on the spot repairs, to keep your appliances safe and compliant.

Report

You’ll receive a digital PAT testing Certificate listing all tested appliances, their location, the test results and any repairs carried out – perfect for your Safety records and compliance.

Comply

Our service ensures you meet Health and Safety regulations, insurance requirements, and duty of care responsibilities. With sensible guidance on retest frequency and reminders for retests.