Getting PAT Testing done right is your best policy

PAT testing is a service all businesses need, as every business has electrical equipment, so every business needs to maintain safe electrical equipment. If you are competent in electrical safety then you may be able to do this yourself however, unless you are well trained, experienced and qualified we wouldnt recommend it.

PAT testing is perceived as being easy, but it really isn’t. It’s a technical subject that covers a wide area of expertise, and so your best option is to get a specialist PAT testing company in to check your equipment is safe.

We will do what needs to be done – we’ll do repairs where needed, test what needs testing and provide you with the paperwork you need to ensure you are compliant.

Faulty electrical equipment can lead to an electric shock for the user, or it can overheat and start a fire, potentially damaging property – in fact electrical equipment is identified as one of the main causes of UK fires, so getting equipment checked regularly to make sure it continues to be safe is best practice.

Furthermore, our engineers are experts and understanding all aspects of the safe use of electrical equipment so they can help you maintain a safe workplace by tidying messy cables, addressing socket issues and protecting sensitive servers.

Why do you need PAT Testing?

PAT Testing is ‘preventative maintenance’ – the reason we do it is to comply with the latest regulations for Health and Safety. You are required by law to maintain safe electrical equipment, and if the worst happens, to be able to prove you have done everything necessary, and support your argument with efficient paperwork.

PAT testing is officially referred to as In-Service Inspection and Testing of Electrical Equipment (ISITEE), which determines whether equipment is fit for continued use, or whether maintenance or replacement is required.

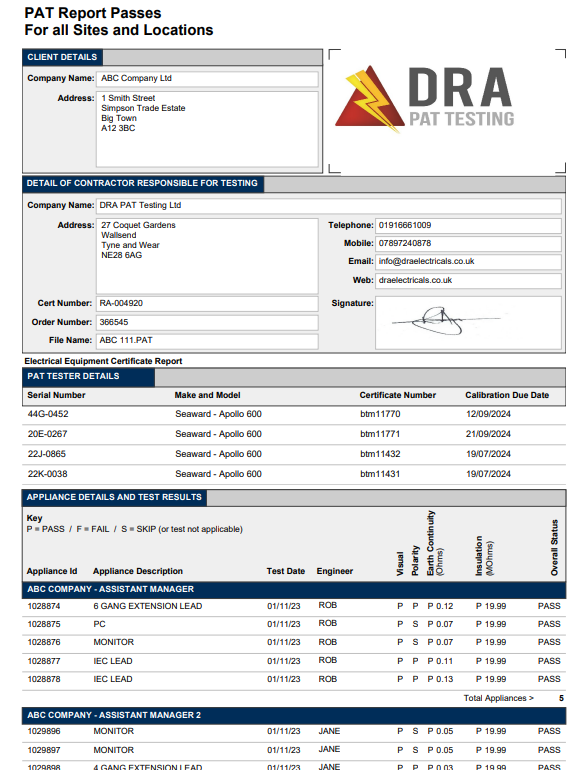

The Inspection and Testing process (PAT) will flag up any maintenance required, and in extreme circumstances, replacement. On completion of the inspection you will be provided with a document that provides you with the records needed. However, this document must include electrical readings and all the necessary information – most PAT companies don’t provide this information, so be careful when you are choosing a supplier.

Every report we issue includes everything you need including electrical test results, a log of maintenance carried out and a breakdown of tests completed.

About our PAT Testing Service

Our engineers are highly trained, qualified and competent to inspect and test electrical equipment. We also have passed DBS checks. Staff undergo regular Health and Safety training and hold CSCS cards.

All items are tested in accordance with the latest British Standards, PATTA and IET guidance.

A Good Certificate Protects You

When you get your PAT Testing Certificate it needs to have certain info. Following industry guidance the report must include confirmation the appliance has passed, so a report with ‘Pass’ on it, is sufficient. The report will list the appliance, the test date, the engineer and that it passed. That’s what you need as a minimum requirement.

However, if the worst happens and you end up in court; to protect you from big fines or possible prison, you need your Certificate to include essential information not provided by most companies, but always provided by us:

- What the electrical test readings were, and that they were within the required parameters

- What repairs were carried out and what parts were supplied

- Why failed appliances failed

With these 3 items on the report, you are much better protected.

When we test an appliance we record the test results and show them on the report, if we carry out a repair we record it on the report – that’s an essential maintenance log of preventative maintenance.

Our engineers take care in their work

As a leading PAT Testing company with a team of highly trained engineers you get peace of mind that your electrical equipment is safe.

You are assigned and engineer and we aim for that person to work with you long term, building a relationship and understanding to help you maintain safe electrical equipment in your business.

Our engineers give every appliance the attention it needs, carefully checking every plug, every cable, every appliance, in full, and making any repairs necessary. This includes tidying up messy tangled cables under desks, reducing the number of extension leads in use and assigning every item tested a new unique ID number.

All tests comply with the latest British and ISO standards, IET and PATTA guidance.

PAT Testing Frequency – Sensible Guidance on Retest Periods

PAT testing companies want to return every year to test all your equipment, but this is not always the best policy:

- A risk assessment will determine what needs testing and how often; some appliances need checking every 3 months, others every 2-3 years could be sufficient.

- Most companies get PAT testing done annually because it saves hassle, it’s convenient and ensures they’re always up to date – it is best practice.

Annual checks show you are making a major effort to stay compliant with regulations including the Electricity at Work, but frequencies more or less often can be determined by a risk assessment dependent on the environment, users and equipment types. More information on PAT Testing Frequency.

High standards and training mean a quality service every time

Our PAT Testing Certificate Reports meet the standards required by ISO (including ISO27001 Security), CQC (Medical Inspectors), Ofsted (Schools inspectors), CHAS, Constructionline, HMO landlord license applications, etc.

Repairs including replacement plugs are included in the price; there are no hidden charges.

We believe in continuity and rapport – working with you long term benefits you and us so we try to send the same engineer(s) every time, so they get to know your business to best advise you how to maintain safety.

When tests are due again we send you a reminder, with a proposed date to do the work, our clients appreciate this.

We all have enhanced DBS; we’ve worked with Durham Constabulary since 2015, so we regularly pass stringent security checks – if they trust us to access their restricted areas, you can be assured your business is in safe hands. We also work with many schools, hotels, etc.

✔ Experienced, friendly, professional, qualified, competent engineers who have enhanced DBS.

✔ Free remedial repairs including repairs to the flexible cable, repairs to the existing plug, replacement plugs and fuses.

✔ Old Messy labels removed; and new ones applied neat and discreet.

✔ Guidance on risk based retest periods that ensure compliance, changeable as your business changes or grows.

✔ Reminders for retests when approaching renewal

✔ Guidance on ways to improve safety

✔ Engineers who can test portable and fixed electrical appliances.

✔ An Itemised PAT Testing Certificate Report that include electrical readings and maintenance records sent by email asap after the job.

“Hello, I am Richard. I am going to try to explain to you a bit about what we do and what you get when you choose us to PAT test your electrical equipment.

I have tried to make it interesting, but there is an opportunity to waffle on and bore you to tears so this is just an overview. If you really want to learn more you can delve into our many blogs, or just book an appointment and we’ll come do the job. After all I’m not interested in what my accountant does as long as he saves me tax, and you probably don’t care what we do, as long as we ensure your equipment is safe and give you a certificate.

Before I get into the nitty gritty I just want to let you know these things, especially if you are still considering which PAT testing company to use”.

If there is ever an accident, and an electrical appliance is to blame, even if it has been tested YOU are still held responsible. You have to be able to prove in court (if it comes to that) that you did everything you needed to do to make sure the appliance was safe. If you can provide a PAT Testing Certificate it will help you; but if you can provide a report that lists all the appliances tested, what tests were done, the results obtained (readings not just ‘pass’), and any repairs carried out that will be much more help. If your report includes just a ‘pass’ comment, and no information, you may not be covered, as anyone can make that up. All our reports include all the information you need to provide evidence that you have taken the appropriate action. Many of our competitors supply reports that’s not worth the paper they’re written on – you can spot these companies because they charge low rates per item (usually less than £1).

If we find a faulty appliance that needs repair, in most cases, we do the repair free of charge, automatically. Most other companies charge for this, or don’t do it at all. Simply they fail the item – why would you want an appliance that can easily be repaired, failed so you can’t use it? You can spot these companies because they charge low rates per item (usually less than £1).

We don’t rush our work – our engineers are encouraged to find faults and fix them; they’re also encouraged to do a thorough job, to tidy messy cables and to make sure your workplace is safer when they leave. We don’t target our engineers ‘per item’, we simply want the job done well so you are happy. Many companies out there, especially the ones who charge low rates, want their engineers to achieve unrealistic targets (approx. 500 items per day – we do about 2-250 items).

We are based in the North East – many companies claim to be based in the region, who aren’t. We are based in Wallsend, and our engineers work from home in North Shields, Newcastle and Blyth. That company with purple labels are in Thirsk, the one with Green paper labels are in Leeds; the one that claims to be based in Newcastle is really in Edinburgh, and so on. There’s a really good company in Newcastle, as well as us, and another good one in Durham, but there’s not loads of us up here.

We’re experts at what we do – we are highly skilled, competent, qualified, experienced PAT Testing engineers. I have done this job since 2009, before that I worked for a bank. I have built up a good business with a great reputation and train my team to work like I do – Kyle, Rob and Jane all have high standards and are very good at what they do. A good PAT tester works with electrical equipment every day.

The Benefits of PAT Testing

PAT Testing is proven to be the best method for ensuring your electrical equipment is safe. PAT, as a regular preventative maintenance programme, it ensures all reasonable steps have been taken to comply with health and safety legislation.

It also helps to protect you and your insurance when claims are made against you or your business, for loss or damage as a result of neglected or faulty electrical equipment.

- Regular tests help you maintain safe electrical equipment

- The engineer assesses the suitability of an appliance for the environment it is being used in to help you comply with The Provision and Use of Work Equipment Regulations 1998

- PAT testing records can be used to demonstrate compliance with the Electricity at Work Regulations 1989

- Regular PAT testing helps you to comply with The Workplace (Health, Safety and Welfare) Regulations 1992

- Regular PAT tests in rental property help you comply with The Housing Act 2004 (England and Wales)

- PAT tests before the start of a tenancy help a landlord comply with The Ministry of Housing, Communities and Local Government’s guidance

- Regular PAT tests help you comply with The Electrical Equipment (Safety) Regulations 2016

- PAT testing finds plugs that don’t meet the Plugs and sockets etc. (Safety) Regulations 1994 and corrects it.

There are 10,000% more counterfeit electrical goods in the UK now than 20 years ago

Our engineers are fully aware of counterfeit goods and we’re always updating our knowledge of them, so if you them, we can spot them. Counterfeit electrical appliances, such as fake Apple chargers, are a major fire risk and have been proven to be the source of many domestic fires.