Information regarding Earth Continuity Testing/Earth Bond Test

The IEE Code of Practice recognises four test situations.

- 1. Type Testing to an appropriate standard

- 2. Production testing

- 3. In-Service testing

- 4. Testing after repair

This document is limited in covering topics concerned with In Service Testing only – we are not a training company, and this page may not always be up to date.

Electrical Safety relies on a good earth connection (or insulation)

This is the testing carried out as a routine to determine whether the equipment is in a satisfactory condition.

In-Service testing will involve the following:

- (a) Preliminary inspection

- (b) Earth continuity tests (for Class 1 equipment)

- (c) Insulation testing (Which may sometimes be substituted by earth leakage measurement)

- (d) Functional checks.

Electrical testing should be performed by a person who is competent in the safe use of the test equipment and who knows how to interpret the test results obtained. This person must be capable of inspecting the equipment and, where necessary, dismantling it to check the cable connections.

If equipment is permanently connected to the fixed installation, e.g. by a flex outlet or other accessory, the accessory will need to be detached from its box or enclosure so that the connections can be inspected. Such work should only be carried out by a competent person.

The Earth Continuity Test is also known as the Earth Bond Test:

This test is carried out using the earth pin of a plug, but getting the earth point is only possible on ‘class 1’ appliances. A class 1 appliance must have an earth. A class 2 appliance doesn’t have an earth so it’s not possible to test it for earth; such an appliance has double insulation which is usually enough protection and a test on this appliance type would measure the resistance of the insulation. Check out our double insulated post for more information.

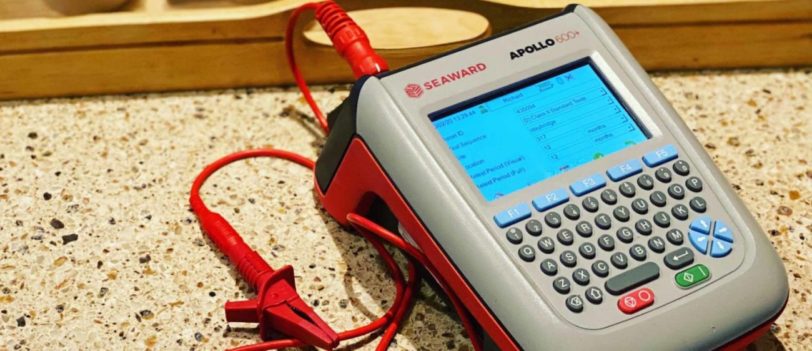

When carrying out an earth test the appliance is plugged into the PAT Testing machine and the earth bond lead from the machine is clipped on to an exposed metal part of the EUT. A current is then sent from the PAT machine around the circuit that has been created.

Readings should show less than 0.1+R Ohms (where R is the resistance of the lead)

Tested at a current of 1.5 times the rating of the fuse and no greater than 25A for a period of between 5 and 20 seconds or with a short-circuit test current within the range 20mA to 200mA.

If you need your electrical equipment PAT testing get in touch with us today.

Contact us to arrange your electrical testing

You may find this article on double insulation interesting.