Reasons why electric shock accidents involve portable appliances

One of the biggest problems in any workplace is the use of portable electrical equipment. Referred to as portable appliances, electrical equipment fitted with a plug presents a high risk of becoming damaged and thus dangerous.

Portable appliances include any electrical appliances that can be plugged in and include computers, kettles, toasters, heaters, hair driers, power tools, etc.

Considered the main problem with portable appliances is that they have a flexible insulated electric cable, which is used to connect it to the plug and aid its movement, that can easily become damaged. Additionally not all cables are secured to the appliance, and are plugged into it themselves.

12 Reasons why electric shock accidents involve portable appliances

A high proportion of electric shock accidents in the workplace involve portable appliances. Here are just a few reasons for this:

- Using inappropriate equipment for the job

- Using inappropriate equipment for the environment

- Overloading extension leads

- Adding to or ‘daisy chaining’ extension leads, potentially overloading them

- Misuse of appliances, such as running cables under carpets and furniture, where the insulation can become damaged

- Using the flex to pull the plug out of the socket

- Trapping cables in doors and drawers

- Allowing incompetent people to carry out repairs

- Allowing poor repairs to take place, such as the use of insulation tape

- Allowing incompetent people to test equipment, such as cheapest bidding ‘sticker jockeys’

- Continuing to use defective equipment

- Failing to regularly inspect, test and or maintain electrical equipment.

Reasons why electric shock accidents involve portable appliances

Portable equipment can be problematic, whether its in your kitchen, office or workshop, even your laptop and phone chargers present a risk. If you are not aware of the hazards and or you don’t implement measures to control them you may be exposing yourself, employees and other users to the risk of an electric shock.

If you don’t take preventative measures to maintain safe electrical appliances you will find that before too long the appliance will deteriorate.

A deteriorated appliance, not repaired, presents a real danger to human life.

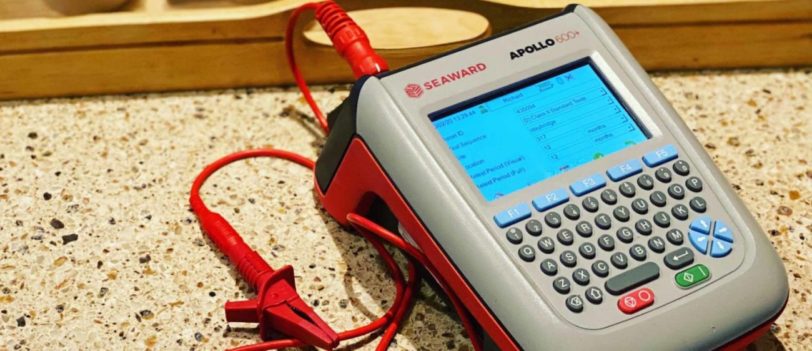

To ensure your equipment doesn’t become dangerous you need to implement a preventative maintenance programme including regular inspections and testing of your equipment.

The aim is to test and repair appliances before they develop a fault, so regular checks should be carried out, appropriate to the risks associated with the appliance and its use.

These regular inspections need to include repairs to defective appliances, or replacement of any that are beyond repair (or removal from use).

Records should be kept of inspections, maintenance, tests and repairs to show that you’re taking appropriate measures and flag up any trends.

The main electrical problem in any workplace is portable appliances; appliances are moved frequently and so easily damaged, easily tampered with and difficult to keep track of.

Deciding how often to test your appliances can also be quite tricky as there are so many factors to consider; in fact this being such an arduous task is one of the main reasons why so many businesses get appliances tested annually.

DRA PAT Testing provide portable appliance testing services across the North East of England; contact us today to discuss your needs or to get a quote.