Articles related to electrical equipment safety tips mainly around portable appliance testing

12 Reasons why electric shock accidents involve portable appliances so often (number 8 may shock you!)

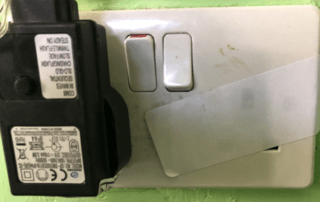

Reasons why electric shock accidents involve portable appliances One of the biggest problems in any workplace is the use of portable electrical equipment. Referred to as portable appliances, electrical equipment fitted with a plug presents a high risk of becoming damaged and thus dangerous. Portable appliances include any [...]