How often do I need to get PAT Testing done?

How often do I need to get PAT Testing done?

A question we get asked, probably more often than any other question, is “How often do I need to get PAT Testing done?”

You’d think this would be so easy to answer, that the internet would be full of answers, that the HSE would tell us exactly what we need to do. That there would be guidance available to help us. Unfortunately, there is no simple answer. The reality we have to operate in, is the answer is far from straightforward; although we would like to keep it simple and give you a straight answer.

Most customers want to know how often PAT testing needs doing for the wrong reasons; the want to know, so they can save money – why get it done every year if every 2 will do, saving half the costs. I get it, that makes perfect business sense, but you’re looking at it from the wrong angle.

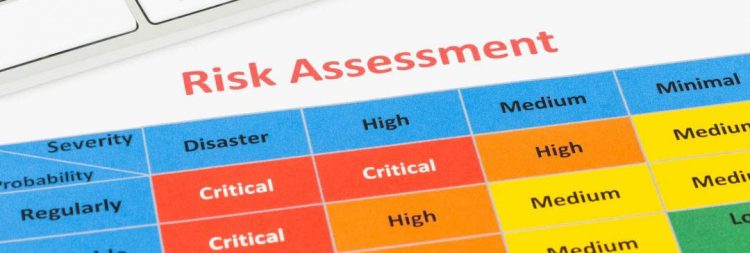

You need to consider the risks associated with the equipment, and your workplace, and take those into account to determine how likely the chance is of danger arising if you continue to use the equipment without getting it checked.

What advice is available?

In truth, next to nothing. The HSE did use to offer guidance on this, but they have not updated their guidance since the HSG107 (3rd Edition) document, Maintaining Portable Electrical Equipment, published in 2013.

This document explained that determining frequency of inspection and testing was a matter of judgement by the duty holder (i.e. manager, business owner, etc.), and should be based on a risk assessment. So you need to do a risk assessment. Most businesses now, do a risk assessment which says they need to get PAT testing done; they then take the guidance of their PAT tester, and operate to that requirement, or if they have sufficient competency in electrical safety, the decide their own frequency.

Document HSG107 provided a guidance table that could be considered, but it had a lot of variations to consider. HSG107 recommended that 110v construction equipment be tested every 3 months, but we know from experience, very few sites do this.

It also recommended that earthed equipment such as Kettles should be tested every 1-2 years, and that extension leads attached to computers should be tested every 1 to 5 years, which is not much help. More on this is available on our PAT Testing Frequency page.

Roll forward to 2025, and a lot has happened since 2013 – health and safety is a lot stricter, there have been a lot of accidents and major incidents, but electrical safety is improving. However, there has been no new guidance released, in fact, there is less availability of new guidance now than there was in 2013.

Whether guidance comes from the PAT tester, the Fire Brigade, an insurance investigator, a risk assessor etc, the recommendation given generally is to test every portable appliance every year (at least) – whilst this may not strictly follow what little guidance there is, it’s done because if we say do it less often, and something happens, we may be held accountable, or liable, and we don’t want that.

However, from experience, of testing since 2009, and completing over 1.5million tests (to Nov 2025) we recommend annual testing as standard in most working environments, not least because it seems to be the preference of insurance companies. Some workplaces may need all or some of their equipment checking more often.

So, some are told annual testing is the recommendation; others are told every 2 years is fine, and some are told it doesn’t need doing at all! In my humble experience, those that get told it doesn’t need doing at all, are usually told by someone who isn’t competent to answer the question, so that person should be ignored.

This all leads to confusion on what a duty holder is expected to do. Your PAT tester (or other guide) isn’t trying to pull the wool over your eyes, it’s just the guidance available to us, is the same guidance available to you, and we don’t want to get sued by you, if we advise one thing and an accident occurs.

The added problem, is people who bang on about ‘PAT testing not being a legal requirement‘; which is correct because PAT testing as a term is confused, and not used in official documents. But as that’s the term everyone knows, its easier to go with it.

The Electricity at Work Regulations place the responsibility on employers to ensure that electrical equipment is maintained in a safe condition; how you interpret that is based on risk, and that is the interpretation varies so widely.

In 2020 the Institute of Engineering and Technology updated its Code of Practice, and attempted to phase out the phrase ‘PAT testing‘, and replaced it with Electrical Equipment Testing (EET), which makes perfect sense, as all electrical equipment requires testing, not just portable appliances, however, ‘PAT testing‘ remains commonly known and used both in and outside the industry, because it is such a widely recognised term.

Nowadays whether you get electrical equipment inspection and testing, electrical equipment testing, portable appliance testing or PAT testing, you’re getting the same thing – you’re getting your electrical equipment tested. We just call it PAT testing, because that’s what everybody understands, so why reinvent the wheel!

All electrical equipment needs testing, whether it is portable, stationery, movable etc. Basically if it comes with a plug attached, and is portable from the mains by way of unplugging, then it needs testing by a PAT tester. Some appliances will have had the plug removed, and be hard wired to the mains through a ‘spur’. These also need a test, although a full test can’t be done, because the hard wiring inside the ‘spur’ is the responsibility of the electrician. So generally a competent PAT tester will do what is called a Point to Point test between and earthed metal point on the spur, and earthed metal point on the appliance. Anyway, we are digressing, confusing the situation even more!

What I am trying to say, is don’t worry about whether the appliance is portable or not; we’ll manage it and if you need to do anything else, we’ll tell you.

What advice about PAT testing frequency can we give?

Lets consider initially most small business; they’re generally low risk environments, such as small offices with well-managed equipment and only a few select users, such as the business owner. The required frequency of testing can be far more relaxed than in workshops, factories, building sites, or workplaces where equipment is moved more often and subject to more ‘stress’ – wear and tear.

Those workplaces where there is more chance of wear and tear such as mechanics workshops and factories, require more frequent testing.

Places like offices, where computers sit on desks and never move, may pose less risk, and so may not need testing annually, but a hair salon, where tools regularly come into contact with customers, especially those with wet hair, the risk is higher.

Some people ‘in the know’ still argue that a frequency based inspection process, whereby different items in the same workplace should be tested at different frequencies is best. However, having tried this many times, and seen the problems it causes we know, if it can be avoided then it should be.

Annual may be too often in some scenarios, it’s certainly a lot less hassle than doing kettles on one period, computers on another, hoovers on another, power tools on another, and so on, and keeping up to date when equipment is replaced, lost, added to, etc.

What do we recommend? Don’t leave your re-testing more than a year, do it more often for higher risk equipment, or less often for less risk, but make sure you have a water-tight risk assessment to show that that is ok. Want to save yourself the hassle? Do what thousands of others do; get tested annually.

Annual is best, because it is the easiest system to manage, remember and keep up to date.

However, it should never ever be dismissed completely; not doing anything is not best practice, and will only eventually lead to trouble. The goal is not to test for the sake of it, but to keep people safe and demonstrate compliance through a risk based approach.

If you are unsure whether your current PAT schedule is appropriate to your situation, now would be a good time to rethink your options.

Getting the right frequency in place protects your equipment users, your business premises, your peace of mind, etc. and it can save you time, money and unnecessary work whilst strengthening your overall health and safety position.

What happens if there is an accident?

If there is an accident, as you are responsible for managing the risk, the investigators will want to know what you have done to prevent that risk, and they will want to see acceptable evidence. If you show them a PAT report from 3 years ago, they’re going to ask why you didn’t get it done last year, or the year before that. If you can show why that was an acceptable timeframe, that may be ok, but if it was to save money, that’s not ok.

Consider this – was it worth saving a few hundred quid, if a person died? Or your business premises had a fire?

A 3 yearly inspection may be perfectly fine in the perfect office set up, but does that exist? If the monitors and computers are fixed to the desks – the monitors on ‘arms’ and the computers in boxes, so they can’t be moved or tampered with; if the cables are neat and tidy, running through quality trunking with plenty of space to breathe, and freedom of movement (not tight and thus not under associated stress), then each one into a floor box socket or onto an extension lead that is not overloaded, then you may be able to argue your case. But not for every appliance in the office; some things will not be like this, some will be moved more, or used by lots of people – printers for example, or a fan, radio, heater, or the laptops everyone takes home every night. Ok so we may not include the laptop in the PAT test, but its charger is, and that will be unplugged every night, coiled up in a haphazard fashion putting strains on the cable, then untangled at home, then wrapped up again to bring back to work; these all add to the risk of damage. So your monitors may get checked every 3 years, but other items like these mentioned, or the kitchen appliances will need doing more often.

And what about the server? Yes it’s worked fine for years and never been unplugged, but how do you know the quality of the appliances? Are they safe, they may be fine for 6 years, but in the 7th they develop an itch, overheat and catch fire – if they’d had a proper test (been unplugged), you’d be covered because you had done sufficient checks.

Is now a good time to consider your PAT testing options?

There is no better time than now.

Get in touch with us and we’ll help. The best course action is to book us to PAT test your equipment. At the inspection we can review your position and make recommendations. Then we can progress from there.